The LED will light up with dits and dahs. Use the 330Ω resistor to connect the anode to the ground rail of the breadboard. Wire the cathode of the LED (long leg) to pin 13 of the arduino. (7) Next lets wire in an LED and its 330Ω current limiting resistor. This simply controls the brightness of the screen. One leg goes to the ground rail, one leg goes to the 5V rail, and the center pin connects with V0 of the LCD display. Searching LCD1602 on amazon shows a lot of similar products. If you do not want to modify this project, make sure you get a matching display. You can see the soldering along the top where a pin header had been placed (not by me). Here is a close up of the LCD display I used for this project. (5) Use hookup wire to wire the appropriate pins of the LCD display to the arduino as shown below. Settle the LCD into the breadboard when you are able. (4) You may need to solder a pin header on to your LCD display in order to secure it in a breadboard. Check your LCD display documentation to see how these pins are arranged. This seems to be labeled “LED” and “LED” on other LCD displays, including the one shown in the cartoon schematic above. I believe that the “A” and “K” refer to the power and ground to the LED of the display respectively.

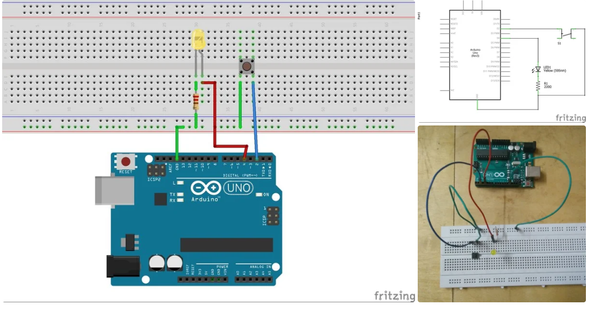

(3) The connections on the LCD display that I used for this project are listed in the table below. All subsequent 5V connections should go into the 5V rail of the breadboard. All subsequent ground connections should go into the ground rail of the breadboard. Connect the 5V rail to the 5V pin on the arduino. Connect the ground rail to one of the ground pins on the arduino. (2) Establish a ground rail and a 5V rail on your breadboard. (1) Refer to the cartoon circuit diagram below. PART 2: WIRE COMPONENTS ON BREADBOARD AND ARDUINO If you would rather use a breadboard for the audio part, the wiring cartoon is shown below. The TRS sleeve is wired to ground as shown below.Īnd this is how the board looks without any additional mark-ups. I drew in the green lines to show how the components are connected on the underside of the board. The tip of the TRS jack is wired to the capacitor (labeled “Audio in”), while the sleeve of the TRS jack is wired to ground (not shown).Īnd how it actually looks when soldered to the protoboard. You can see how I did it in the sketch below. (7) Use a protoboard (or go ahead and just use a breadboard) to wire the components together. This is the explanation provided in the learnelectronics video. The reason to include this part is because the arduino apparently cannot handle negative currents. Apparently this biases the audio input current so that the current is always positive with respect to ground. The AC current from the audio input is then subjected to the voltage divider created by the 10KΩ resistors. The capacitor is to stop stray DC current from passing through. Note: My understanding of this circuit is that audio from a cw source enters as AC current. You will notice that I twisted the audio connector wires in the final version. This is an idea of how the audio input module will look after it is all constructed. (6) Add heat shrink tubing over the sleeve wire connection. (5) Consider twisting the wires together for neatness sake. (4) Solder a 10″ length of wire to the posterior sleeve area of the TRS jack. (3) Use heat shrink tubing to cover the initial wire to the tip. Check for continuity with tip, and no continuity with the ring or sleeve. (2) Solder about 10 inches of hookup wire onto the appropriate posterior part of the TRS jack that is in continuity with the tip. (1) Remove TRS jack from a dead pair of headphones, or acquire the jack in some other way.

#Arduino morse decoder lcd dsp code#

How tough would it be to build a morse code decoder? Or otherwise known as a cw (for continuous wave) decoder for the ham radio operators out there. While following the tutorial and watching my inspirational messages such “Hello World” and “I like pizza” transfer from the desktop arduino IDE to the the little screen, the first independent break out project that I wanted to build popped in my mind.

#Arduino morse decoder lcd dsp series#

The 48th video in Paul McWhorter’s youtube series on arduinos interfaced with an LCD display. As I mentioned on here before, I have been studying both the arduino and electronic circuits.

0 kommentar(er)

0 kommentar(er)